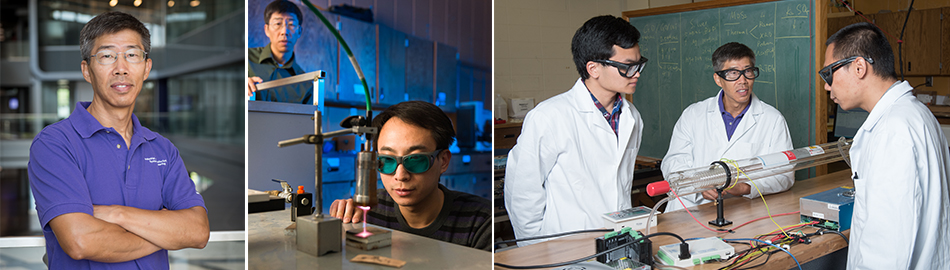

Shuting Lei and his team specialize in difficult-to-machine materials like superaolloys, glass and ceramics: think combustion chambers, touch screens and hip replacements. These materials are desirable to manufacturers because of their strength, durability and flexibility. Yet their properties are extremely difficult to cut.

Using laser machining processes, such as the game-changing femtosecond laser, Lei and his researchers seek novel techniques to manufacturing difficult-to-machine materials like superalloys, glass and ceramics, paving the way for innovative applications in a variety of industries, such as biomedical, energy, photonics and more.

ACTIVE PROJECTS

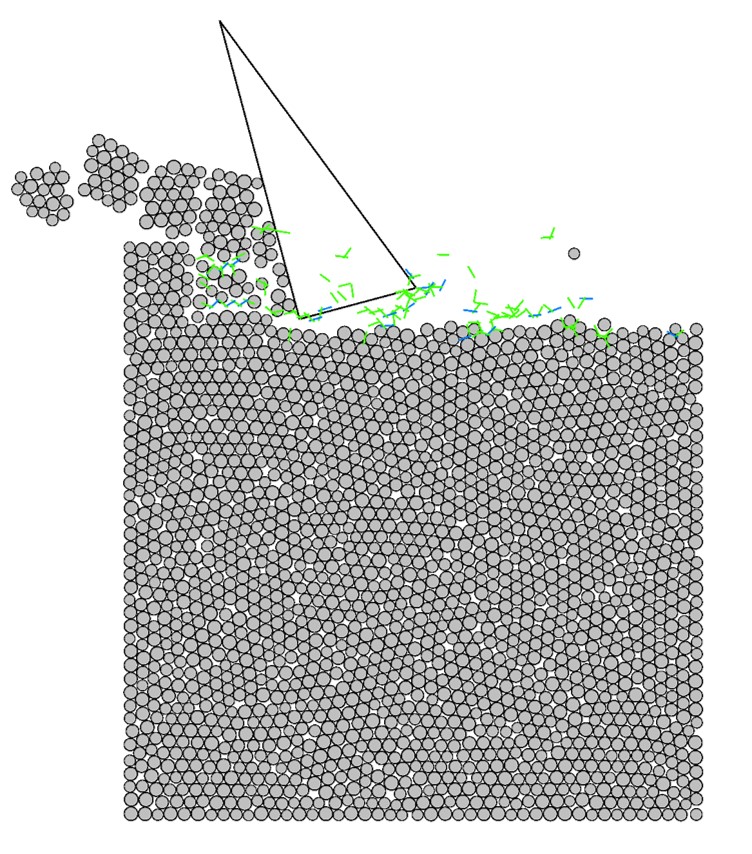

High performance machining of brittle materials by controlled crack propagation

Precision parts made from a wide variety of brittle materials have broad applications in healthcare, biomedical, energy, photonics, and automotive industries. Maintaining high surface quality with high speed machining of brittle materials and reducing random crack propagation that results in surface/subsurface cracks and strength degradation of the machined parts. Existing techniques rely on polishing, a very slow and costly process, to achieve high surface quality. Lei is developing a novel laser micromachining process to generate seed cracks inside the workpiece to make subsequent material removal by a cutting tool easier.

Precision parts made from a wide variety of brittle materials have broad applications in healthcare, biomedical, energy, photonics, and automotive industries. Maintaining high surface quality with high speed machining of brittle materials and reducing random crack propagation that results in surface/subsurface cracks and strength degradation of the machined parts. Existing techniques rely on polishing, a very slow and costly process, to achieve high surface quality. Lei is developing a novel laser micromachining process to generate seed cracks inside the workpiece to make subsequent material removal by a cutting tool easier.

Nanosecond laser micromachining in bulk silicon

In the field of 3-D ultrafast laser micromachining, researchers have been working to achieve permanent modifications in bulk silicon and other narrow-gap materials with applications in writing 3-D waveguides, microfluidic devices and sensor networks. While attempts utilizing conventional laser micromachining have seen little success, Lei’s research team is studying 3-D modification inside silicon wafers using laser pulses with 1.55µm wavelength and 3.5 ns pulse duration to control its shape and size and achieve permanent modifications. Their work will have applications in the direct writing of 3-D monolithic devices for silicon photonics.

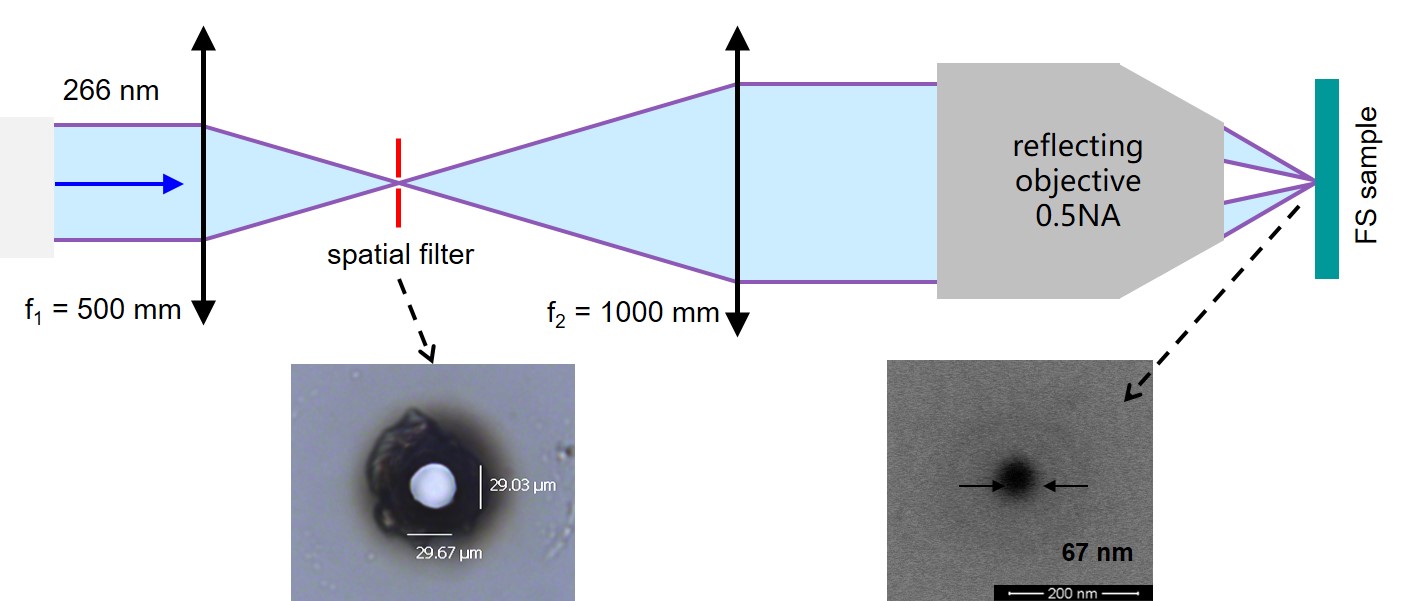

Femtosecond laser micro/nanomachining

With distinctive features such as ultrafast temporal duration, high peak power and large spectral bandwith, the femtosecond (fs) laser is a unique tool for micro/nano machining applications. Lei’s research encompasses both the fundamentals of fs laser matter interaction and its applications. For fundamental research, his research team studies the early stage of laser matter interaction and the evolution of photoionization and carrier dynamics. On the applications front, they use spatially and temporally shaped beams to study laser surface texturing, laser peening, laser scribing of thin film materials and 3-D modification inside material. With the emergence of next generation reliable and affordable fs laser systems on the horizon, their goal is to develop high performance fs laser machining techniques for industrial applications.