Pretensioned Concrete Crossties for High-speed Railways

When Japan introduced their Bullet Train in the 1960's high-seed transportation exploded across the world. Today this is a multi-billion dollar industry used by numerous countries for passenger travel and freight service. As the demand for this technology continues to grow, so does the need for a better railroad design.

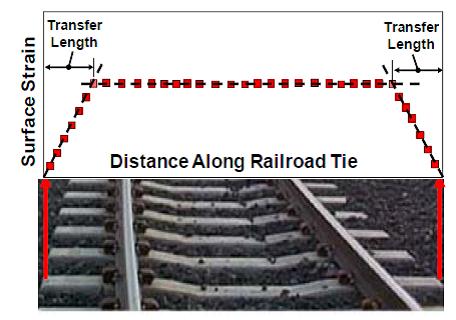

There are approximately 3,000 ties per mile of railroad track in the US. The current design uses pre-stressed concrete, which is susceptible to break under high-speed pressure. When a tie breaks it costs the government hundreds of thousands of dollars to repair. The rate at which these ties are currently breaking is cause for major concern.

Research and design of a stronger rail tie via bulk manufacturing

Research and design of a stronger rail tie via bulk manufacturing

John Wu is one of four engineers contracted by the United States Department of Transportation/Federal Railroad Administration to research the manufacturing of a stronger rail tie. Joining him are two researchers from the Carl R. Ice College of Engineering — Robert Peterman, civil engineering, and Terry Beck, mechanical and nuclear engineering. In the first phase of their research, Wu and his team developed a non-destructive testing method used to detect the strength of the rail tie before it is sold and shipped. Today this is a patented product used internationally. The team is currently working on phase two of the research project, which if successful will save the U.S. billions of dollars over time.

Research objective — Design an affordable rail tie that can withstand the pressure of high-speed transport and can be manufactured in bulk at an affordable price.

- Wu is responsible for selecting the material and designing the shape of the bar.

- Peterman is tasked to identify the concrete mix used to enclose the bar.

- Beck tests the pre-stressed force based on the design created by Wu and Peterman.

Additional research interests

- Mathematical programming

- Network optimization

- Applied operations research

- Transportation and air traffic systems

- Digital image processing

- Pattern recognition

- Material handling

- Robot control strategy

- Flexible manufacturing systems design

- Group Technologies

- Machine loading